MIWE thermo-rollomat

The gentle giant.

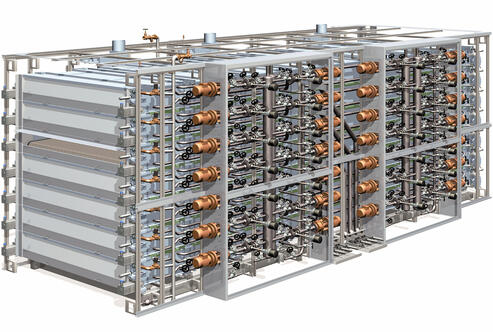

MIWE thermo-rollomat tunnel oven

The highest-level thermal oil tunnel oven

If you click on the video, a request will be sent to Youtube or Google with your IP address. Data protection

Experience the MIWE thermo-rollomat from all perspectives in this 3D model.

Would you like to see how the MIWE thermo-rollomat would fit into your bakery?

Simply activate the augmented reality feature (AR) with your smartphone or tablet!

What makes the MIWE thermo-rollomat tunnel oven so unique

Praise from the experts

If you really want to know how well and reliably the MIWE thermo-rollomat oven bakes in practice, you might not want to ask us first. And certainly not one of our market competitors. But one of your colleagues instead. Best of all, ask one of the well-known bakers who have been so satisfied and successful with this oven for so many years that they have long since been operating a second, third or even fourth line with it. They do this because, as far as their baking quality is concerned, no other thermal oil system on the market can even come close to matching the MIWE thermo-rollomat. It won't let you down: Thermal oil technology from MIWE is among the best you can get on the market today.

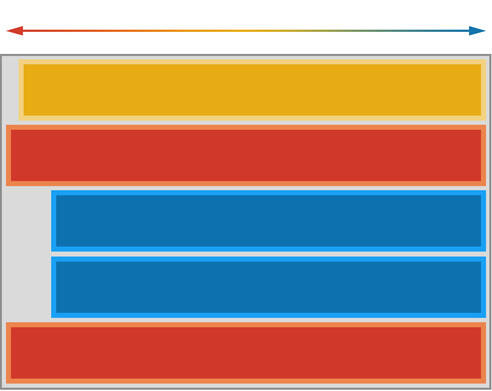

You have the choice: continuous or step operation

Where consistently large quantities of similar products (for example 25,000 rolls per hour) are to be baked with the best quality, at the same time and efficiently, the single-oven, continuously operating MIWE thermo-rollomat with a baking surface of up to 145 m² is truly in a class of its own. With similarly high throughputs, but with greater variance in the baked goods spectrum, however, the multi-oven version (up to 7 ovens, up to 300 m² baking surface) really outshines its competitors, because it allows you significantly more flexibility in the individual baking processes with additional ovens and variable timing. In step mode, it is possible to bake either in continuous cycles or in whole batches (when the belt is stopped). What fits better with you and your products?

There are good reasons for its baking uniformity

During the development of the multi-oven version of the MIWE thermo-rollomat, we took great care to ensure that the same amount of oil was moved at the same flow rate through tubes with the exact same geometry in each oven module. Only then, and with an intelligent design of the heating channels, can the uniformity of the baking results be achieved, for which the MIWE thermo-rollomat is now widely valued. Due to the horizontal blowing in of the air

Lifespan

Year after year, your MIWE thermo-rollomat will give you pure pleasure again and again. Because it is designed for longevity. With frequency-controlled drives, for example, which ensure smooth start-up and minimal wear - with maximum fail-safety. Or with the special, new roller chain, which also reduces wear and ensures particularly smooth and silent running. And because at MIWE you can rely on a qualified service staff that not only knows its stuff, but also takes care of everything.

Wide range of belt materials

Depending on what you intend to bake and how you intend to bake it, the MIWE thermo-rollomat can be equipped with a standard wire mesh belt, the patented special hinged plate belt, which rests on the entire surface and prevents belt imprints from forming on the baked goods, or (in the single-oven version) with a stone slab belt. So you can even bake "stone oven bread".

Variable solutions for loading and transfer

You also have the choice of using the ideal loading belt for your products: in addition to the tried and tested fabric belt, there is also a silicone-coated belt (washable, dirt-repellent, anti-adhesive) and a robust stainless steel mesh belt that can be used (among other things) for tins. In each case, the transfer takes place at the same level and synchronously, with the least possible stress to your baked goods. It is therefore also ideal for soft doughs, trays, tins and dough pieces on foil. Of course, we also provide you with required auxiliary equipment, such as stamping or spraying devices.

Saturated steam

For the highest product quality, the flow of steam (time, quantity, quality) can be individually adjusted to a great extent and, moreover, closely monitored to ensure constant humidity and temperature. After the steam zone, an optional turbulence zone can be set up. The steam extractor works efficiently and can be combined with a heat recovery system such as the MIWE eco: nova.

Ingenious: the floating baking chamber

Due to the free-floating arrangement of the baking chambers and the heat exchanger plates in the base frame, the MIWE thermo-rollomat has as separate, self-contained oven units. Strong inner insulation makes it possible to operate the ovens at different temperatures with top and bottom heat, without heat penetrating into neighbouring ovens. In addition, it counteracts thermal stresses in the system if, for instance, only individual ovens are in operation. Conclusion: More flexibility, higher operational reliability, extended service life.

The hot core of the system: the central boiler unit

This is where the gentle heat comes from: the central heating boiler, which is designed to meet the needs of your oven and, as a result of maximum operational safety, usually as a tandem system with two boilers operated in parallel in a separate boiler room.

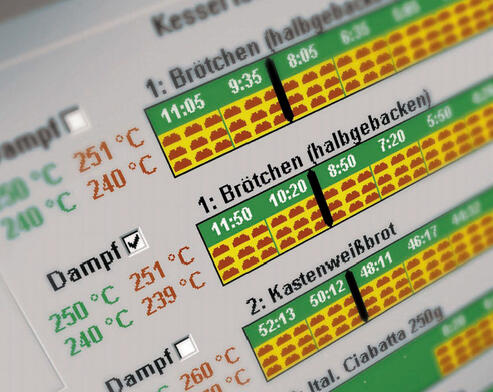

The control center

If you want to achieve uniform results, you need a control unit that supports this to the fullest. But which is flexible and uncomplicated to use at the same time. One which visualises the operating procedures, continuously monitors the operating conditions and from which all system components can be operated largely automatically. Such a control system is the touch screen monitor of the MIWE thermo-rollomat, which of course can also be connected to our remote services via a network.

How the MIWE thermo-rollomat helps you save energy

Saving energy is more important than ever. MIWE has the answers.

Efficient steam extraction, can be combined with the heat recovery system MIWE eco:nova

Particularly energy-saving, free-floating baking chambers

Strict reduction of heat radiation through particularly strong intermediate insulation between the separately heated ovens

Energy saving and flexibility thanks to cooker groups that can be switched on and off individually

Reduction of thermal bridges and radiation through multi-layer insulating mats and improved thermal insulation

Sample system: Discontinuous production with a high level of manual flexibility

The task:

- Simultaneous production of different hard rolls and bread in large quantities. Maintaining a high level of flexibility. Future expandability

Our concept:

- Independent process islands for dough processing, proofing and baking.

Highlights:

- Wide range of products possible

- High level of flexibility

- The sub-units can be divided into separate sections.

- Easy to expand

Documents

Product information

MIWE impulse

More production ovens

You prefer a personal consultation?