Loading systems & transport: Intelligent solutions for efficient baking

Semi and fully automatic loading systems from MIWE are now an indispensable part of every bakery. Our loading aids and transport systems impress with their ergonomic handling, ensure a structured and energy-optimised material flow and take the strain out of work.

Efficient feeding

Automated, integrated, optimised: Our feeding systems ensure higher productivity

Holistic consulting

Planning, implementation, support: MIWE experts ensure perfect processes

all around.

Planning and testing on site

MIWE loading & transport

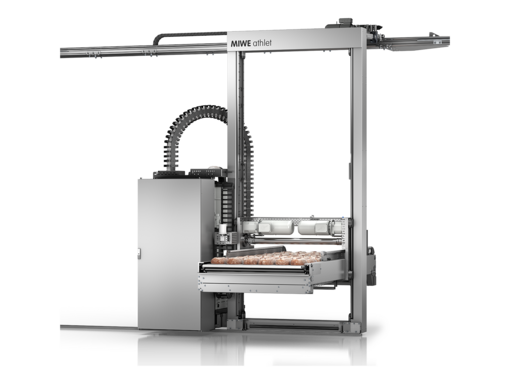

Staff are expensive and often hard to come by. MIWE's sophisticated loading systems allow production ovens to be loaded semi-automatically and fully automatically. Our focus is not only on automated loading and unloading, but also on transport to and from the production area in order to reduce the physical strain on production staff and guarantee precise processes. For an optimum material flow even in the tightest of spaces and therefore an efficient, profitable workflow.

Efficient loading. It's simple.

Would you like to provide some relief to your employees and optimise the productivity of your bakery? With MIWE loading solutions, it's easy to do. Our tried-and-tested systems can control up to six different ovens, handle the loading and unloading of baked goods largely automatically, save on labour resources and ensure ergonomic working on an advanced level.

What about the way to the oven? Maximum freedom.

Regardless of which types of refrigeration you prefer, which baked goods carriers you use and which forms of finishing you use before or after baking: our solutions adapt to your processes. Docking stations for cross transport, loading belts with or without automated spray belts, flour applicators or cutters, as well as plank infeed and outfeed for working with peelboards...all this can be integrated into your concept. And there's also clever equipment add-ons, such as a dough turning device, a pusher and movable knife edges.

Sustainable loading technology. Maximum flexibility.

Would you like to invest for the long term but still remain flexible? MIWE's robust loading systems stand for low maintenance as well as precision in transport and loading - and for a wide variety of baked goods. Thanks to the modular expandability, feeding and transport systems can be adapted to the current needs of your bakery at any time.

MIWE engineering and planning - Smart bakery concepts

Automated. Ergonomic. Consistently efficient.

MIWE loading and transport systems ensure ergonomic handling, a streamlined, energy-efficient material flow and measurably higher output.

MIWE. Your experienced partner for reliable oven loading

At MIWE, you get the perfect processes that you have always wanted for your bakery. Automation solutions from a single source, cleverly networked and customised. We can draw on many decades of experience and realise the ideal combination of loading technology, production ovens and refrigeration technology for you. Contact us, we will be happy to advise you on your options - whether for newly planned or existing systems.

MIWE loading solutions: Bake more efficiently!

Our transport and loading systems ensure the right flow in the bakery and relieve your employees of a large part of the physically strenuous work. From the simple feeding aid to the high-performance system, which can even automate large throughputs to a very large extent. Thanks to their flexibility, our feeding systems can be optimally integrated into your operation.

MIWE feeding systems: These are your advantages

- We analyse the production capacities and growth potential of your bakery and develop the perfect system for you.

- Automation processes increase efficiency, improve oven utilisation, save on labour and energy costs, and reliably ensure consistent product quality.

- Our systems are flexibly customisable and offer numerous options, such as an integrated hoover for quick and easy oven clean-up.

- We offer solutions for artisan bakers as well as large-scale bakery chains, and support you in the transformation towards a future-oriented business.

How MIWE transport and loading systems improve your baking processes

Success stories: MIWE loading systems on site at a local bakery

Your path to the right automation solution – whatever your throughput.

We analyse your capacity and processes to design a flexible solution (from semi to fully automated) that reduces costs, stabilises workflows and ensures consistent quality.

Test our technologies in the MIWE Live Baking Centre in Arnstein

Pictures are patient - only in practice does it become clear whether a product delivers what it promises. At the MIWE live baking centre in Arnstein, you can put our oven and loading systems through their paces in a fully equipped demonstration bakery. The motto "Meet the experts" is to be taken literally: Not only can you ask our master bakers and dough technologists in person, we also offer comprehensive expert workshops and seminars. We would be happy to help you plan your trip!

See what you get: The MIWE planner

Who on earth would ever buy something blindfolded? With the MIWE planner, our virtual 3D bakery planning tool, you can see in advance how the new loading system will fit into your bakery, how the processes will run in your operating environment, and how peripheral devices can best be grouped around the ovens and refrigeration systems. The ideal solution for complex requirements can thus be developed, where the smooth interaction and interlocking of several components must be carefully considered.

Energy optimisation in your bakery

The production of baked goods is a very energy-intensive and therefore expensive process. Even the most economical systems cannot fundamentally change this. This is why MIWE has a separate business unit, MIWE energy, dedicated to energy flows in the bakery - with a clear goal: reduce, recover and reuse. In other words: reduce energy consumption, recover used energy and utilise it sensibly. The latter in particular is often a weak point in energy concepts, especially for energy consultants from outside the industry, i.e. energy experts who are not familiar with the very specific conditions of bakery production. Not so with the holistic energy concepts from MIWE energy, because our energy experts are at home in the bakery.