MIWE roll-in e+ model year 2022

The rack oven

MIWE roll-in e+

Continuous improvement process, the MIWE way

Over the past several years, the demands placed on rack oven systems have noticeably increased.

- A wider range of products, including more spaced bread varieties

- Shortened baking times (especially in combination with vacuum conditioning)

- Shorter recovery times between baking processes

- Goods that are natural with a long shelf life and therefore more delicate and generally more prone to flaws

- Hotter temperatures

Our newest MIWE roll-in e+ model complements existing functions with the latest demands from the world of baking.

MIWE variobake

For products with more individuality and a strong character.

Now also available for the MIWE roll-in rack oven.

The finely regulated burner capacity allows the energy intensity transferred to the product to be adapted extremely precisely to the individual requirements of the respective baked goods. This gives companies the opportunity to position themselves distinctively in the competitive market with products that have a strong character and more individuality.

The "medium" intensity is supplemented by two additional levels. Puff pastry and Danish pastry products with a fine crumbly bite as well as sponge cake, sand cake & related products in particular benefit from the "gentle" process and juicier results. The "aggressive" level prevents, for example, breads with 100% rye from spreading due to the strong energy input.

*Available for the MIWE roll-in with 2-stage burner.

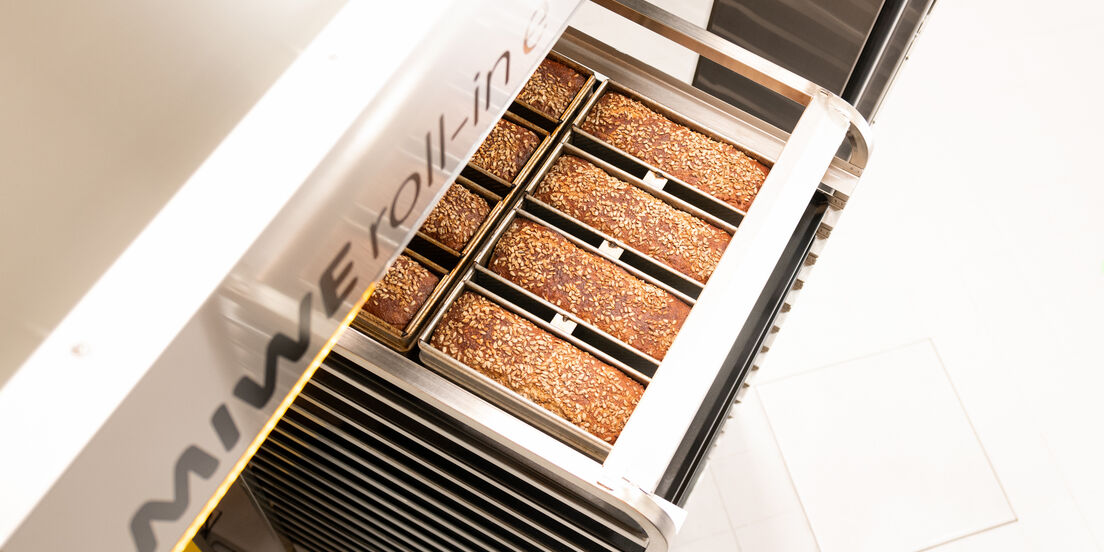

Intenso steam

For better results with tin sets and tighter loading.

Our newest model, with its Intenso steam jets, will join the ranks of our renowned steam-sprayer models. It distributes steam evenly and uniformly throughout the baking chamber, especially when baking with tightly-packed tin sets or trays.

The Intenso steam breaks up blocks of cold air extremely effectively using several bursts of steam and a few well-timed circulator pulses, ensuring more evenly baked goods all the way to the centre of the tray.

Booster function

For faster batch-after-batch baking and pre-baking at higher temperatures.

The new booster function reduces typical temperature drops when opening the rack oven door by continuing the burner operation for a certain amount of time.

This eliminated the start-up time that would otherwise be necessary, enabling faster batch-after-batch baking. This is also beneficial for products that require high initial heat, such as pure, unmoulded rye bread.

Autostart: ready for baking

Simply start baking straight away.

Get started as soon as the first person enters the bakery – this is now possible with the new MIWE Autostart ready for baking function. Using this setting, it is now possible to specify in advance when the MIWE roll-in should be heated up and ready for the first rack trolley – even for twice a day.

In the background, the oven also analyses its residual heat to save valuable energy while heating up.

And safety has also been considered. If the rack oven has not been used within 2 hours, it switches itself off and jumps to the next autostart time.

Detailed explanations and video instructions on the most important functions

- MIWE variobake

- Intenso steam

- Booster function

- Autostart: ready for baking

- Transferring baking programmes

- Uploading images via USB

- Connecting to MIWE smart baking suite

- Control-assisted calibration

- Control-assisted baking out

- Service page, burner installers

- MIWE aircontrol

- MIWE atmospheric baking

- MIWE delta baking

- MIWE magnetic area

- and many more...

Request your personal offer for the MIWE roll-in e+ now!

What makes the rack oven MIWE roll-in e+ so unique

Focus on energy efficiency

Everything about MIWE roll-in e+ is optimised for maximum energy yield. This clear focus on energy efficiency starts with the smallest components, such as the door seal, and continues with patented technical refinements.

Atmospheric baking

Put an end to weather-induced problems. Instead, achieve optimal evenness and better baking quality, whatever the weather. That is guaranteed by atmospheric baking from MIWE, having proven its absolute reliability for many years. Winner of the Südback Trend Award 2016. Included as standard in the MIWE roll-in e+.

MIWE variobake

The comparison clearly shows the influence MIWE variobake has on the characteristics of the baked goods. From gentle, to medium and aggressive, you can bake exactly as you like using the energy input.

MIWE aircontrol

MIWE aircontrol 2.0 improves the patented technology for controlling air volume in the baking chamber. More sophisticated fine-tuning is now possible, especially for the lower levels. This is particularly beneficial for baked goods with a high sugar content where crumbling should be prevented at the beginning of the baking process, such as with eclairs or macarons.

Refined: MIWE delta-baking

Conventional oven systems have only two burner conditions: on or off. Full throttle or idle. With the MIWE roll-in e+ you will reach your goal with more delicate attention – MIWE delta-baking provides you with two energy levels of different strengths. That is particularly beneficial for pastries and fine baker’s wares.

MIWE flexbake®

The clever automatic system that compensates for process fluctuations. This means that one and the same baking program always delivers a perfect baking result – regardless of whether the trolley is only half full, the doughs are colder than usual or the door has been open too long.

MIWE frozen dough piece baking

For baking directly from frozen without the need for additional proofing. The process combines controlled thawing followed immediately by baking and, thanks to continuous pulses of steam and air at the start, ensures the best gloss and a perfect finish.

MIWE Heat flow

Optimum flow geometry together with the optimised heat storage wall control the hot air in the baking chamber so precisely that ideal baking results are achieved on every single tray.

Ready to connect! Online in no time

It is exactly as simple as it sounds: you simply connect a network cable to the oven and the control unit takes care of the rest (configuring the IP address, network masks, etc.). For security and clear identification, our systems are also equipped with a certificate, meaning that nothing stands in the way of logging into the MIWE Bakery Cloud.

Also available as a double rack oven

What's better than a MIWE roll-in e+? That's right: two MIWE roll-in e+ – or even better – getting the double rack oven straight away. There is room for two racks and they are baked in the usual quality and time. The advantages are obvious: compared to baking in two ovens, it saves energy as well as installation and maintenance costs, while also reducing procurement costs. All in all, lower costs and more profit.

Experience the MIWE roll-in e+ from all perspectives in this 3D model.

Would you like to see how the MIWE roll-in e+ would fit into your bakery?

Simply activate the augmented reality feature (AR) with your smartphone or tablet!

How the MIWE roll-in e+ helps you save energy

Saving energy is more important than ever. MIWE has the answers.

Low energy consumption thanks to flow-optimised heating gas conduction

Efficient batch-after-batch baking due to the heat storage wall

The clever steam system in cascade design saves water and therefore energy

Efficient and forward-looking baking with MIWE Autostart and MIWE Eco mode

Request your personal offer for the MIWE roll-in e+ now!

See for yourself: Watch the video and discover the many reasons for the MIWE roll-in e+

If you click on the video, a request will be sent to Youtube or Google with your IP address. Data protection

Energetically impressive details

Everything about MIWE roll-in e+ is optimised for maximum energy yield. This clear focus on energy efficiency starts with the smallest components, such as the door seal, and continues with patented technical refinements and the option of integration into the diverse energy recovery systems from MIWE.

Heat storage wall

Keeps energy in the baking chamber, minimises peak loads and reduces the connected load. For efficient batch-after-batch baking.

MIWE eco mode

Saves valuable energy during "breaks in baking" and is therefore the best compromise between low energy consumption and being ready to bake at short notice.

Steam-proof door seal

Permanent hermetic steam proofing: the seals on the door can be easily adjusted at any time.

Energy recovery

Everything from a single source. Connect your MIWE roll-in e+ to the diverse energy recovery systems of MIWE and save money – without any interface issues.

Heat-insulated glass

Keeps the heat right where it belongs – inside the rack oven – yet offers a wide view into the baking chamber.

Cascade design

The high-performance steamer allows for a reduction in water volume and, thanks to the clever cascade design and higher efficiency, also ensures reliable, rapid evaporation and distribution.

Patented heating gas conduction

Significantly reduces energy consumption: patented heating gas conduction with additional flue gas channel which is also used for steam heating.

MIWE eco:wing

The MIWE eco:wing is has an advantageous position in the flue gas when it comes to energy and performs its mission silently and discreetly during every baking process: saving energy. (Availability in your country upon request).

Multi-layer insulation mats

Multi-layer design, gap-free installation, improved insulating value – and all long-lasting. Because unlike compact mineral wool, there is nothing here that can collapse.

Ergonomically impressive details of the MIWE roll-in e+

The aspiration at MIWE is always to combine simplicity, quality and functionality in an attractive design. That's why all of the carefully thought-out design elements on the MIWE roll-in e+ have one clear goal: making it as easy and pleasant as possible for you to work with your rack oven.

LED remote indicators

Elegantly integrated into the steam hood and control column, the brightly lit status indicators provide information on the current operating status of the rack oven and are clearly visible even from a distance.

10.4" glass display

Makes it easy to operate and provides all the important information at a glance: the large display of the MIWE TC touch control system.

Oven mitt storage

The oven mitts (no matter the style) can be happily stored on the impact protection, so they are always within reach – without having to bend down.

Impact protection

The glass display is well protected thanks to the discreet but nevertheless effective impact protection. This means that even a fully loaded rack trolley cannot cause any damage.

Installation possible on three sides

A MIWE roll-in e+ rarely goes it alone. This is why is can be easily encased on three sides. All maintenance-relevant components are conveniently accessible from the front.

Extra flat ramp

This allows even the most delicate baked goods to be placed in the oven gently, safely and without much effort. Of course, it comes out just as easily.

MIWE auto-start

Define when the oven should be ready to bake the next day. For the entire week or every individual day.

Magnetic control column

Thanks to the magnetic surface on the control column, bakery knives and other items always stay well stowed and within easy reach.

Soft-close door

The optional soft-close automatic door no longer needs to be locked manually. Just leave it ajar and it closes automatically. This is conveniently done using one hand.

Hygienically impressive details

For perfect oven hygiene, the MIWE roll-in e+ is inherently designed to make it especially difficult for dirt to accumulate. But everyone knows that even the most hygienically perfect rack oven needs to be cleaned from time to time. Fortunately, your MIWE roll-in e+ makes that easy as can be.

Easy to clean

Even the glass panels of the door can easily be kept clean. The outer panel can be detached in just a few quick steps – for convenient cleaning of the insulating intermediate space.

One-piece base

Sturdy as well as hygienic: the heavy-duty steel rotating plate rests in a one-piece base. Dirt can no longer collect here.

Hygienically flawless

Flat surfaces – even in the baking chamber – provide the ideal conditions for oven cleaning and hygiene.

Request your personal offer for the MIWE roll-in e+ now!

Whatever your plans…

The range of products baked in rack ovens has increased significantly in recent years. Nowadays it also includes more and more breads. This is one of the reasons why baked goods are often baked much hotter today, driving up the performance requirements.

In addition, natural, long-process proofing products have been in high demand for some time. However, these are usually much more delicate and prone to flaws, especially in the critical baking phase.

The MIWE roll-in e+ offers options for dealing with all of these requirements and sensitivities. Whatever your plans – your new MIWE roll-in e+ is ready.

Discover and test the MIWE roll-in e+

Do you believe that the proof is in the pudding? Then we cordially invite you to the MIWE live baking center, where our MIWE roll-in e+ is waiting for you to try it out. Contact us.

What our customers say about the MIWE roll-in e+ rack oven

The MIWE roll-in e+ combines one-of-a-kind technologies

Accessories

- Exhaust hood

- Steam condenser

- Rack trolley

Options

- Fixed program control MIWE FP

- MIWE delta-baking

- MIWE atmospheric baking

- Soft-close door

Technical information

MIWE roll-in e+

Size 60x60

|

Rack trolley |

1 |

|

Baking tray size |

60 / 60 |

|

Baking area in m² |

7.2 |

|

Exterior dimensions in cm (W x D x H) |

139 x 151.5 x 256.5 |

|

Minimum chamber height in cm |

285 |

|

Connected load in kW |

50 - 60 |

|

Heating type |

Oil / gas / electricity |

Size 60x80

|

Rack trolley |

1 |

|

Baking tray size |

60 / 80 |

|

Baking area in m² |

9.6 |

|

Exterior dimensions in cm (W x D x H) |

154 x 160.5 x 256.5 |

|

Minimum chamber height in cm |

285 |

|

Connected load in kW |

60-75 |

|

Heating type |

Oil / gas / electricity |

|

Rack trolley |

1 |

|

Baking tray size |

60 / 80 |

|

Baking area in m² |

10.6 |

|

Exterior dimensions in cm (W x D x H) |

155 x 160 x 272.5 |

|

Minimum chamber height in cm |

301 |

|

Connected load in kW |

60-75 |

|

Heating type |

Oil / gas / electricity |

Size 60x100

|

Rack trolley |

1 |

|

Baking tray size |

60 / 100 |

|

Baking area in m² |

12 |

|

Exterior dimensions in cm (W x D x H) |

172 x 176 x 256.5 |

|

Minimum chamber height in cm |

285 |

|

Connected load in kW |

70 - 85 |

|

Heating type |

Oil / gas / electricity |

|

Rack trolley |

1 |

|

Baking tray size |

60 / 100 |

|

Baking area in m² |

13.2 |

|

Exterior dimensions in cm (W x D x H) |

172 x 176 x 272.5 |

|

Minimum chamber height in cm |

301 |

|

Connected load in kW |

70 - 85 |

|

Heating type |

Oil / gas / electricity |

Size 67x108

|

Rack trolley |

1 |

|

Baking tray size |

67 / 108 |

|

Baking area in m² |

13.8 |

|

Exterior dimensions in cm (W x D x H) |

181.5 x 185 x 256.5 |

|

Minimum chamber height in cm |

285 |

|

Connected load in kW |

80 - 95 |

|

Heating type |

Oil / gas / electricity |

|

Rack trolley |

1 |

|

Baking tray size |

67 / 108 |

|

Baking area in m² |

15.2 |

|

Exterior dimensions in cm (W x D x H) |

182 x 185 x 272.5 |

|

Minimum chamber height in cm |

301 |

|

Connected load in kW |

80 - 95 |

|

Heating type |

Oil / gas / electricity |

MIWE roll-in e+ double rack

Size 60x80

|

Rack trolley |

2 |

|

Baking tray size |

60 / 60 |

|

Baking area in m² |

17.3 |

|

Exterior dimensions in cm (W x D x H) |

216 x 229 x 295 |

|

Minimum chamber height in cm |

335 |

|

Connected load in kW |

125 - 130 |

|

Heating type |

Oil/gas |

Size 60x100

|

Rack trolley |

2 |

|

Baking tray size |

60/100 |

|

Baking area in m² |

21.6 |

|

Exterior dimensions in cm (W x D x H) |

226 x 229 x 295 |

|

Minimum chamber height in cm |

335 |

|

Connected load in kW |

135 - 140 |

|

Heating type |

Oil/gas |

Special features

- MIWE aircontrol (patented)

- MIWE flexbake® (partial loading)

- MIWE delta-baking

- MIWE frozen dough piece baking

- MIWE atmospheric baking

- MIWE eco mode

- MIWE auto-start

- MIWE variobake

- Intenso steam

- Booster function

- Multi-layer insulation mats

- MIWE heat flow

- Magnetic control column

- Impact protection

- Oven mitt storage

- Installation possible on three sides

- Optional door hinge

- Flat ramp

- Freedom to choose the burner

- Heat storage wall

- Patented heating gas conduction

- MIWE eco:wing (available in your country upon request.)

- Heat-insulated glass in the door

- Connection to energy recovery systems:

MIWE eco:nova | MIWE eco:box | MIWE eco:steam

- Hygienic, flat surfaces

- One-piece base

- Completely splash-proof on the outside

- Door glass panels can be opened for cleaning

- Network connection for convenient monitoring of the data using MIWE sbs

- Maintenance-relevant components accessible from the front