MIWE thermo-static

Thermal oil expertise

One-of-a-kind technologies in the thermo-static

What makes the MIWE thermo-static so unique

Exclusive to MIWE: Atmospheric baking

Put an end to weather-induced problems. Instead, achieve optimal evenness and better baking quality, whatever the weather. That is guaranteed by MIWE’s atmospheric baking. Standard in the MIWE thermo-static.

Superior steam technology: MIWE atmo-jet®

The water is transformed into tiny droplets using compressed air before it is fed into the steam device. That creates high-pressure saturated steam particularly efficiently and rapidly for optimal product quality and best sheen.

Real stone-oven bread made easy

The MIWE assist automated loading system with a stone plate frame (optional) takes a load off. And it lets you market the bread baked on it as “stone-oven bread”.

Ergonomics in its purest form

No matter where you look: The MIWE thermo-static impresses with great ergonomic details: The big display makes operation easy, the remote display with modern LED technology (also on the optional exhaust hood) shows you the current oven status from a distance, you only have to lean the optional soft-close automatic door, with the dynamic floor seal for effective steam removal, against the frame – it closes automatically from there without manual locking. It is just as easy to open.

Even more crispness: the turbo system

Where more crispness is required, we recommend the two-stage turbo system (optional), which adds convection to the chamber and is simple to integrate into the baking program. Stage one for gentle browning, stage two for power air circulation and forced de-steaming.

How the MIWE thermo static helps you save energy

Saving energy is more important than ever. MIWE has the answers.

Reduced energy consumption thanks to pinpoint steam technology MIWE atmo-jet

MIWE atmospheric baking: raises product quality, lowers energy costs

Particularly economical LED status lighting

Is the MIWE thermo-static something for you?

Experience the MIWE thermo-static from all perspectives in this 3D model.

Would you like to see how the MIWE thermo-static would fit into your bakery?

Simply activate the augmented reality feature (AR) with your smartphone or tablet!

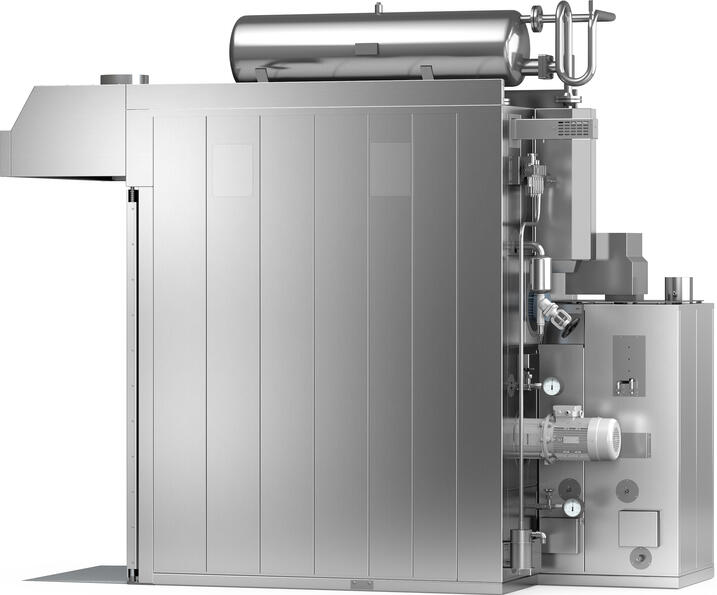

Start immediately: MIWE thermo-static integro

The MIWE thermo-static integro is ideal for anyone who wants to bake with thermal oil, but does not want the complexity (and space requirements) of a separate central heating boiler and the associated piping. In addition to the other benefits of the system, this wagon oven also includes its own boiler. Piggyback and immediately ready for operation without piping or auxiliary units. This reduces energy consumption and increases operational reliability.

What our customers say

Accessories

- Steam hood

- Baking trolley

- Stone slab system

- MIWE slide

- MIWE cool-down system for operation with temperature curves and fast product changeover.

Options

- Stone slab frame

- Two-stage turbo system

- Softclose automatic door with dynamic bottom seal

- Optionally magnetic or axial face seal pump

- Connection to MIWE eco:nova or external steam evacuation accelerator possible

Technical information

2 trolleys / 60 x 80

Model | TS 8.0812 |

Trolley |

2 |

Nominal dimensions of each level in cm |

80 / 120 |

Number of decks | 8 |

Number of baking trays | 16 |

Baking tray size | 60 x 80 |

Baking area in m² | 8 |

Maximum product height in cm | 16 |

Distance between heating plates in cm | 20 |

Dimensions in cm (W x D x H) |

120 x 200 x 256 |

Model | TS 9.0812 |

Trolley |

2 |

Nominal dimensions of each level in cm |

80 / 120 |

Number of decks |

9 |

Number of baking trays | 18 |

Tray size | 60 x 80 |

Baking area in m² | 9 |

Maximum product height in cm | 14 |

Distance between heating plates in cm | 17 |

Dimensions in cm (W x D x H) |

120 x 200 x 256 |

Model | TS 10.0812 |

Trolley | 2 |

Nominal dimensions of each level in cm |

80 / 120 |

Number of decks | 10 |

Number of baking trays | 20 |

Baking tray size | 60 x 80 |

Baking area in m² | 10 |

Maximum product height in cm | 12 |

Distance between heating plates in cm | 15 |

Dimensions in cm (W x D x H) |

120 x 200 x 256 |

2 trolleys / 60 x 100

Model | TS 8.1012 |

Trolley |

2 |

Number of baking trays | 16 |

Number of decks | 8 |

Baking tray size | 60 x 100 |

Baking area in m² | 10 |

Baking tray size | 60 x 100 |

Maximum product height in cm | 16 |

Distance between heating plates in cm | 20 |

Dimensions in cm (W x D x H) |

140 x 200 x 256 |

Model | TS 9.1012 |

Trolley |

2 |

Nominal dimensions of each level in cm |

100 / 120 |

Number of decks |

9 |

Baking tray size | 60 x 100 |

Number of baking trays | 18 |

Baking tray size | 60 x 100 |

Baking area in m² | 11 |

Maximum product height in cm | 14 |

Distance between heating plates in cm | 17 |

Dimensions in cm (W x D x H) |

140 x 200 x 256 |

Model | TS 10.1012 |

Trolley |

2 |

Nominal dimensions of each level in cm |

100 / 120 |

Number of decks |

10 |

Baking tray size | 60 x 100 |

Number of baking trays | 20 |

Baking tray size | 60 x 100 |

Baking area in m² | 12 |

Maximum product height in cm | 12 |

Distance between heating plates in cm | 15 |

Dimensions in cm (W x D x H) |

140 x 200 x 256 |

3 trolleys / 60 x 80

Model | TS 8.0819 |

Trolley |

80 / 190 |

Nominal dimensions of each level in cm |

80 / 190 |

Number of decks |

8 |

Number of baking trays | 24 |

Baking tray size | 60 x 80 |

Baking area in m² | 12 |

Maximum product height in cm | 16 |

Distance between heating plates in cm | 20 |

Dimensions in cm (W x D x H) |

120 x 270 x 256 |

Model | TS 9.0819 |

Trolley |

80 / 190 |

Nominal dimensions of each level in cm |

80 / 190 |

Number of decks |

9 |

Number of baking trays | 27 |

Baking tray size | 60 x 80 |

Baking area in m² | 13.5 |

Maximum product height in cm | 14 |

Distance between heating plates in cm | 17 |

Dimensions in cm (W x D x H) |

120 x 270 x 256 |

Model | TS 10.0819 |

Trolley |

80 / 190 |

Nominal dimensions of each level in cm |

80 / 190 |

Number of decks |

10 |

Number of baking trays | 30 |

Baking area in m² | 60 x 80 |

Baking tray size | 15 |

Maximum product height in cm | 12 |

Distance between heating plates in cm | 15 |

Dimensions in cm (W x D x H) |

120 x 270 x 256 |

3 trolleys / 60 x 100

Model | TS 8.1019 |

Trolley |

3 |

Nominal dimensions of each level in cm |

100 / 190 |

Number of decks |

8 |

Number of baking trays | 24 |

Baking tray size | 60 x 100 |

Baking area in m² | 15 |

Maximum product height in cm | 16 |

Distance between heating plates in cm | 20 |

Dimensions in cm (W x D x H) |

140 x 270 x 256 |

Model | TS 9.1019 |

Trolley |

3 |

Nominal dimensions of each level in cm |

100 / 190 |

Number of decks |

9 |

Number of baking trays | 27 |

Baking tray size | 60 x 100 |

Baking area in m² | 16.5 |

Maximum product height in cm | 14 |

Distance between heating plates in cm | 17 |

Dimensions in cm (W x D x H) |

140 x 270 x 256 |

Model | TS 10.1019 |

Trolley | 3 |

Nominal dimensions of each level in cm |

100 / 190 |

Number of decks |

10 |

Number of baking trays | 30 |

Baking tray size | 60 x 100 |

Baking area in m² | 18 |

Maximum product height in cm | 12 |

Distance between heating plates in cm | 15 |

Dimensions in cm (W x D x H) |

140 x 270 x 256 |

Special features

- MIWE atmo-jet steam technology

- MIWE cool-down system

- MIWE atmospheric baking

- MIWE assist

- Thermal oil heated wagon oven

- Even flow of heat

- Integrated steam device

- LED status light

- Large touch screen with colour display

- Connection to energy recovery systems: MIWE eco:nova

- Hygienic, flat surfaces

- Two operating modes: easy mode, professional mode

- One-piece base

- Completely splash-proof on the outside

- Door glass panels can be opened for cleaning

Documents

Product information

Other rack/wagon ovens

Would you rather have a personal consultation?