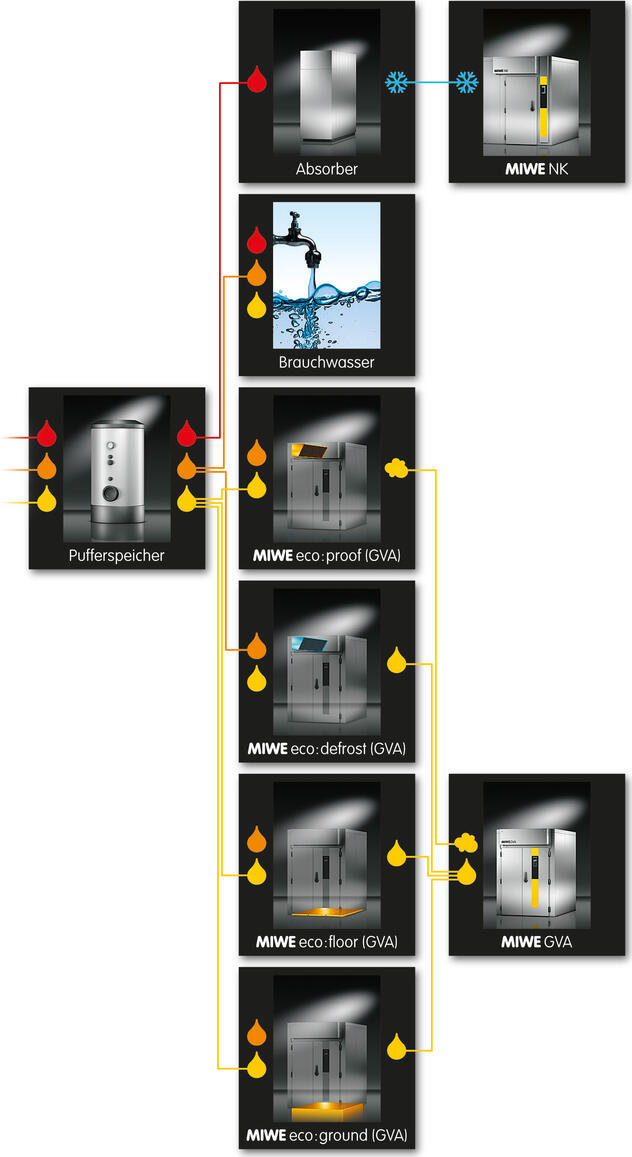

Energy-saving hot water use in bakery refrigeration

High-temperature water supplies an absorber, generating refrigeration out of warmth. Moderate-temperature water flows into the MIWE eco:defrost (a defroster) as well as into the service water circuit, while low-temperature water supplies the MIWE eco:proof (proofing heat), the MIWE eco:floor (prevents the formation of condensation on the floor) and the MIWE eco:ground (protects against frost heave).

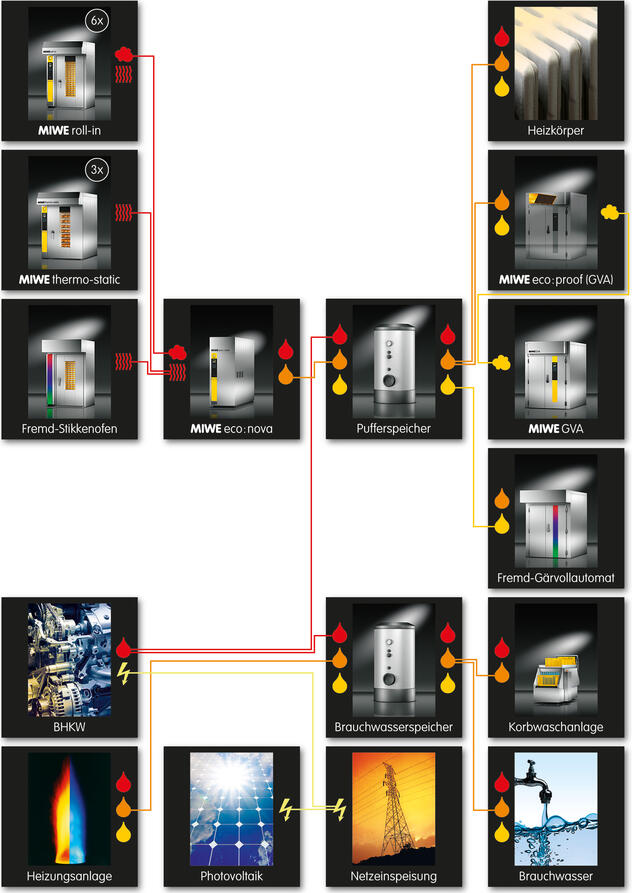

Step by step to a low-energy bakery

In addition to a large MIWE eco:nova, which utilises the waste heat from ten ovens (and only needs one exhaust flue), the solution also includes a block-type thermal power unit and a photovoltaic system.

An intelligent storage and regulating system heats up the service water and room and supplies several fully automatic proofing units (via MIWE eco:proof) and a basket washing unit.

A boiler can help with peak loads.

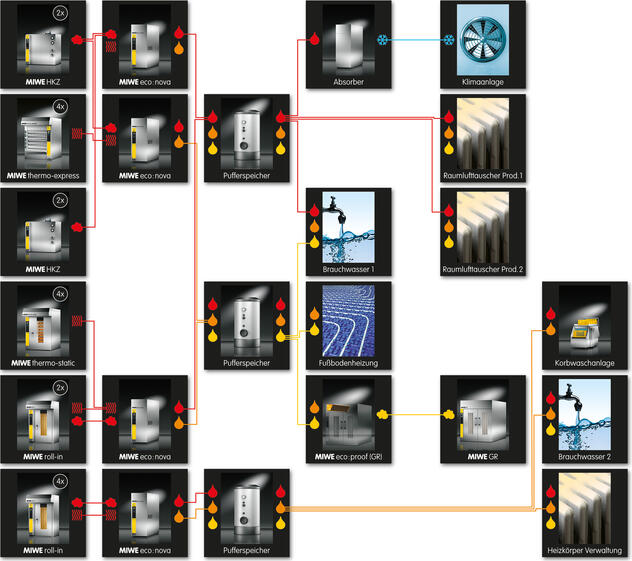

Another example of the diverse possibilities of more complex circuits

The waste heat from a total of 14 ovens and four central heating boilers is captured by four MIWE eco:nova systems (requiring only four exhaust flues rather than 18) and then distributed via three separate buffers and control loops to a variety of heat consumers: a basket washing unit, two service water circuits, three heating circuits (a radiator and air exchanger system, underfloor heating, and (via an absorber) an air conditioning unit).

A convincing concept that provides substantial savings during all times of the year.