MIWE aero e+

Top of the class

Even better. Even more attractive.

The dazzling highlight in your shop: the new MIWE aero e+.

The new generation of the proven MIWE aero e+ brings together first-class baked goods and high-quality design in an impressive manner. The in-shop baking oven becomes an eye-catcher, impresses with its optimised ergonomics and already hints at high baking quality thanks to its exterior.

A stylish LED light bar that extends across the entire width of the baking station provides the current status – visible from afar yet elegantly packed. The gently pulsing light indicates when the baking programme ends in an eye-catching way. The new LED illumination of the baking chamber puts your products brilliantly in the limelight and directs one's gaze to what is important: baked goods for sale. The glossy impression of the baking station is underlined by a completely glazed front surface in noble black.

MIWE aero e+ design models

The MIWE aero e+ combines one-of-a-kind technologies

So, are you interested in the MIWE aero e+ ?

What makes the MIWE aero e+ so unique

The subtle difference: high-performance steam

The MIWE aero e+ is equipped with a high-performance cascade steam device that gets the job done. Thanks to this feature, optimal shine and bloom are guaranteed even with small frozen products, where steam is critical.

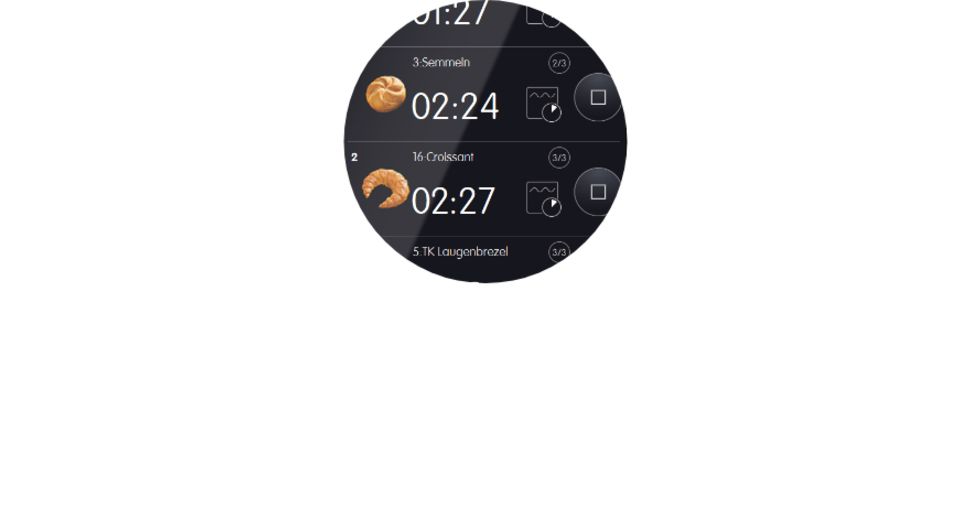

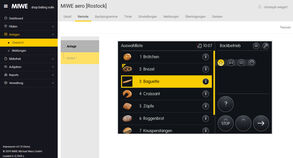

Makes users happy: state-of-the-art control panel

You decide what to do. At its most convenient with MIWE TC touch control and our modern MIWE go! interface With the two-circuit version, the centralised master control makes operating both baking chambers easier (MIWE TC-U).

Perfect frozen dough piece baking

The MIWE frozen dough piece baking feature combines thawing and baking of cooked frozen dough pieces in one process. This helps reduce effort and control the quality of first-class baked goods.

Shines in every respect: the cleaning system

Standard feature: the MIWE easy clean semi-automatic cleaning function. For those looking for perfect hygiene with even more convenience, the optional MIWE cleaning control is the best choice.

All-round carefree package for optimal oven hygiene

Guarantees optimal hygiene: with the optional MIWE everclean package, the large and fully integrated cleaning tank is reliably filled during the annual maintenance check by MIWE Service. So you can safely forget everything that has to do with cleaning your baking station – from re-ordering cleaning products, to storage and refilling, to disposing of the empty containers.

Quality automation with MIWE flexbake®

Although process fluctuations (such as partial loads or dough pieces at incorrect temperatures) are not desirable, they are par for the course. MIWE flexbake® ensures that you always get the same perfect baking results, even with these inconsistencies.

For an ideal indoor climate – without a chimney

The new, modular steam condenser (optional) not only has an improved efficiency, but above all also makes cleaning much easier – for a longer service life and even better hygiene.

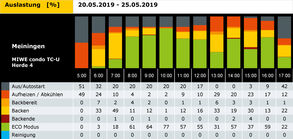

Saves considerable energy costs: MIWE Eco mode

How do you create the ideal oven that is on permanent standby with the most economical use of energy? The answer is easy: With the MIWE eco mode.

Ready to connect! Online in no time

It is exactly as simple as it sounds: you simply connect a network cable to the oven and the control unit takes care of the rest (configuring the IP address, network masks, etc.). For security and clear identification, our systems are also equipped with a certificate, meaning that nothing stands in the way of logging into the MIWE Bakery Cloud.

For snack bakers: gastronomic function (optional)

With its permanent steam technology and core temperature sensor, the MIWE aero e+ is a universal multi-tool for caterers and snack bakers.

How the MIWE aero e+ helps you save energy

Saving energy is more important than ever. MIWE has the answers.

Efficient energy use thanks to MIWE flexbake, the clever automatic capacity regulation system

Energy-saving cleaning through reduced water consumption

Strict reduction of heat radiation through coated glass panes and triple glazing (optional)

Steam valve that keeps the heat in the oven

Efficient and forward-looking baking with MIWE Autostart and MIWE Eco mode

So, are you interested in the MIWE aero e+ ?

Experience the MIWE aero e+ from all perspectives in this 3D model.

Would you like to see how the MIWE aero e+ would fit into your bakery?

Simply activate the augmented reality feature (AR) with your smartphone or tablet!

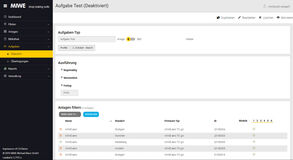

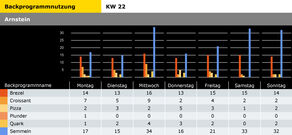

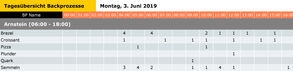

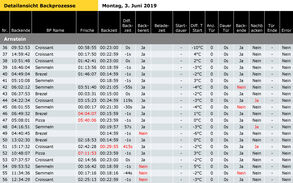

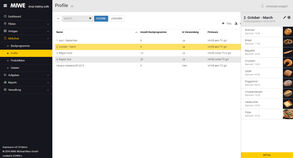

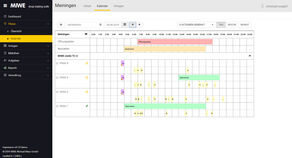

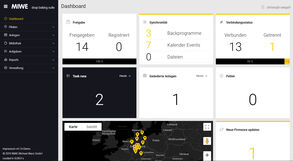

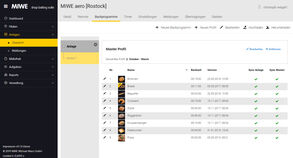

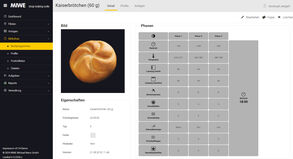

Easily keep an eye on everything: MIWE smart baking suite

Would you like to know how to keep everything under control, even if you have dozens or even hundreds of large baking stations? It's easy: with the MIWE smart baking suite.

This software accesses all your interconnected in-store ovens and delivers the data and information you need in a centralised and well-organised manner. In addition to the system inventory, you can easily monitor and control the status of all systems. You can ensure uniform results through features such as centralised management and synchronised assignment of baking programmes. Extensive calendar and reporting functions allow you to optimise and run all processes and operations more efficiently.

What our customers say about the MIWE aero e+ convection oven

The best of both worlds in baking: MIWE backcombi

Naturally, the latest generation of the MIWE aero e+ is also available in combination with the MIWE condo deck oven as a MIWE backcombi – for maximum flexibility and exceptional baking diversity in the tiniest of spaces. And just to make it a bit more difficult to decide, this dream couple is not only available in umpteen different configurations, but also in a completely black look – if that's what fits your store concept.

The seal of quality: e+

- At MIWE, we are committed to using energy efficiently and making a lasting contribution to sustainable energy conservation. This commitment applies above all to the systems and processes we develop for our customers. MIWE systems that demonstrate this commitment in a special way, and only these systems, are given the e+ seal of quality.

Accessories

- Steam hood

- modular steam condenser

- Storage compartment

- Proofing cabinet

- Underframe

- Base

- Rollers

- Loading system

Options

- Version in black

- MIWE cleaning control

- MIWE everclean

- Triple thermal protection glazing

- Energy optimisation connection

- Gastronomic function

Technical information

Model | AE 4.0604 |

Control system | TC |

Exterior dimensions in cm (W x D x H) |

90 x 85 x 71 |

Total weight (without baking trays) in kg | 163 |

Connected load in kW | 8.5 |

Fuse protection in A | 3 x 16 |

Door hinge | Right or left |

Exhaust hood/steam condenser | |

Exterior dimensions in cm (W x D x H) |

90 x 104 x 19 |

Connected load in kW | 0.2 |

Storage compartment | |

Number of 60 x 40 cm baking trays | 3/4/6/8 |

Height in cm | 32 |

Proofing cabinet | |

Number of 60 x 40 cm baking trays | 10/12/16 |

Control system | FP3 |

Height in cm | 54/61/77 |

Connected load in kW | 2.2 |

Fuse protection in A | 1 x 16 |

Door hinge | Double door |

Underframe | |

Number of 60 x 40 cm baking trays | 4/6/10/12/16/20/24 |

Height in cm | 30/54/61/77/93/103 |

Rollers | |

Height in cm | 4/8/11/16 |

Model | AE 6.0604 |

Control system | TC |

Exterior dimensions in cm (W x D x H) |

90 x 85 x 87 |

Total weight (without baking trays) in kg | 188 |

Connected load in kW | 11.4 |

Fuse protection in A | 3 x 20 |

Door hinge | Right or left |

Exhaust hood/steam condenser | |

Exterior dimensions in cm (W x D x H) |

90 x 104 x 19 |

Connected load in kW | 0.2 |

Storage compartment | |

Number of 60 x 40 cm baking trays | 3/4/6/8 |

Height in cm | 32 |

Proofing cabinet | |

Number of 60 x 40 cm baking trays | 10/12/16 |

Control system | FP3 |

Height in cm | 54/61/77 |

Connected load in kW | 2.2 |

Fuse protection in A | 1 x 16 |

Door hinge | Double door |

Underframe | |

Number of 60 x 40 cm baking trays | 4/6/10/12/16/20/24 |

Height in cm | 30/54/61/77/93/103 |

Rollers | |

Height in cm | 4/8/11/16 |

Model | AE 8.0604 |

Control system | TC |

Exterior dimensions in cm (W x D x H) |

90 x 85 x 103 |

Total weight (without baking trays) in kg | 225 |

Connected load in kW | 15.3 |

Fuse protection in A | 3 x 32 |

Door hinge | Right or left |

Exhaust hood/steam condenser | |

Exterior dimensions in cm (W x D x H) |

90 x 104 x 19 |

Connected load in kW | 0.2 |

Storage compartment | |

Number of 60 x 40 cm baking trays | 3/4/6/8 |

Height in cm | 32 |

Proofing cabinet | |

Number of 60 x 40 cm baking trays | 10/12/16 |

Control system | FP3 |

Height in cm | 54/61/77 |

Connected load in kW | 2.2 |

Fuse protection in A | 1 x 16 |

Door hinge | Double door |

Underframe | |

Number of 60 x 40 cm baking trays | 4/6/10/12/16/20 |

Height in cm | 30/54/61/77/93 |

Rollers | |

Height in cm | 4/8/11/16 |

Model | AE 10.0604 |

Control system | TC |

Exterior dimensions in cm (W x D x H) |

90 x 85 x 119 |

Total weight (without baking trays) in kg | 249 |

Connected load in kW | 19.9 |

Fuse protection in A | 3 x 32 |

Door hinge | Right or left |

Exhaust hood/steam condenser | |

Exterior dimensions in cm (W x D x H) |

90 x 104 x 19 |

Connected load in kW | 0.2 |

Storage compartment | |

Number of 60 x 40 cm baking trays | 3/4/6/8 |

Height in cm | 32 |

Proofing cabinet | |

Number of 60 x 40 cm baking trays | 10/12/16 |

Control system | FP3 |

Height in cm | 54/61/77 |

Connected load in kW | 2.2 |

Fuse protection in A | 1 x 16 |

Door hinge | Double door |

Underframe | |

Number of 60 x 40 cm baking trays | 4/6/10/12/16/20 |

Height in cm | 30/54/61/77/93 |

Rollers | |

Height in cm | 4/8/11/16 |

Special features

- MIWE auto-start

- MIWE cleaning control

- MIWE easy clean

- MIWE eco mode

- MIWE flexbake®

- MIWE frozen dough piece baking

- MIWE gastronomic functions

- MIWE go!

Documents

Additional convection ovens

Would you rather meet us in person?