MIWE flexbake®

Increased learning: the clever automatic system that compensates for process fluctuations

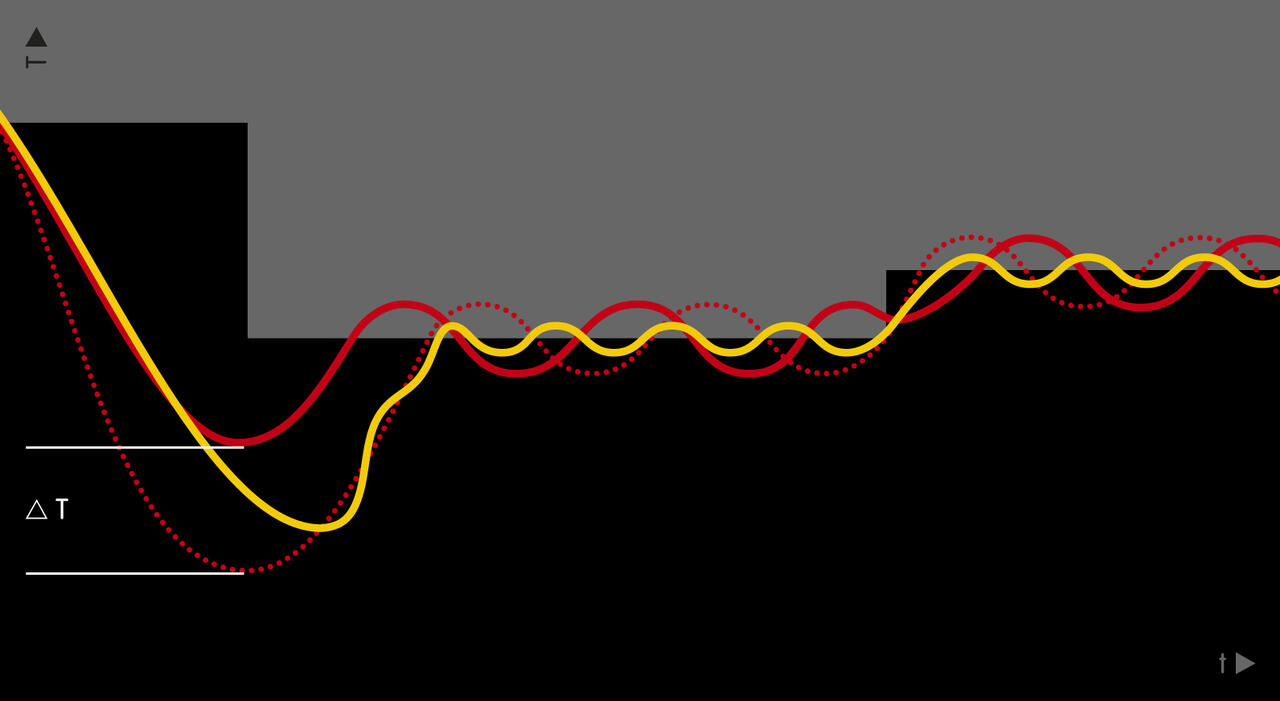

Convection ovens control the baking chamber temperature via the output of the heating element and air circulation. The cold goods put in for baking act as a type of "counter-cooling".

If a lower quantity or warmer dough than usual is put in, this counter-cooling is lower, making the temperature curve in the chamber far hotter. Conversely, a door open for a long time significantly cools down the baking chamber. Such process fluctuations along with similar ones appear time and again; but they result in a baking process optimised for the right operating case only providing sub-optimal results.

Compensation of process fluctuations MIWE flexbake® ensures that the baking station compensates for these process fluctuations and other similar ones automatically, intelligently and flexibly. For this purpose, it is "taught" on a one-off basis (per product/baking program) under ideal conditions (full load, right loading temperature of the goods). It saves the temperature curve recorded and then always controls the baking chamber temperature along this ideal curve in flexbake® mode.

This is how the same perfect baking results are always achieved in the process even with fluctuations.

The advantages of MIWE flexbake®

- Perfect baking results even with deviations from the standard process

- Ideal e.g. for partial loads or other process fluctuations

- Single learning process (per product)

MIWE flexbake® in impulse

In the MIWE impulse, you can find more information on this topic.