Process refrigeration & bakery refrigeration technology

The oven bakes your dough to perfection. But the oven-fresh taste actually comes from refrigeration.

Efficient and flexible baking

Bakery refrigeration increases product quality and efficiency and ensures more attractive working hours

Everything from a single source

Design, implementation, support: MIWE experts provide holistic solutions

Planning and testing on site

Test our systems and ask our experts at the MIWE Live Baking Centre in Arnstein

The oven bakes your dough to perfection.

But the oven-fresh taste actually comes from refrigeration.

For many consumers, oven-fresh variety is the most important feature of a bakery. As soon as they enter your bakery, your customers want to be greeted by an abundance of delicious baked goods and the irresistible aroma of crusty bread and freshly baked rolls. But we owe the ability to offer fresh baked goods at practically any time of day or night not only to the oven itself, but above all to bakery refrigeration - as paradoxical as that may sound.

Bakery refrigeration:

the key to flexibility, efficiency and quality

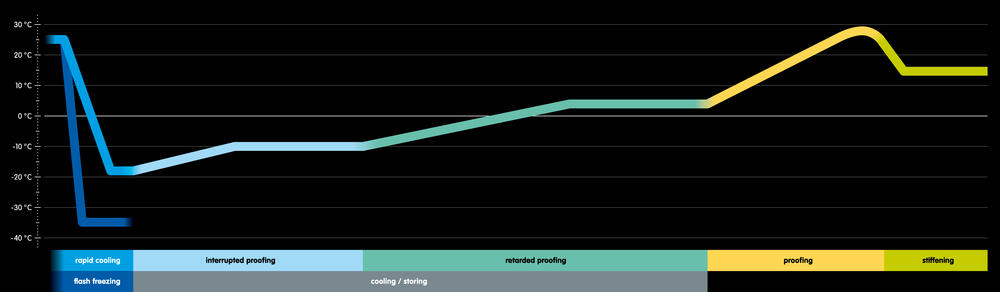

This is because bakery refrigeration technology enables dough preparation and baking to be decoupled in terms of time and space, which is what makes the constant availability of a wide range of products and baking directly in the branch possible in the first place. However, in addition to simplifying operational processes and the possibility of reducing night work, which is unattractive for employees and expensive for you, refrigeration technology offers another decisive advantage that is increasingly becoming the focus of bakers: the targeted increase in product quality by means of skilful control of temperature, humidity and time.

Bakery refrigeration:

A job for the experts

However, effectively utilising the opportunities and possibilities of bakery refrigeration requires far more than just refrigeration technology - namely a deep understanding of the characteristics of the raw material dough, the processes and procedures used and, of course, the workflows during the final baking process - whether in production or in the shop. As a full-service provider, MIWE has the know-how, expertise and experience needed to offer holistic solutions that are better (and can do more) than just the sum of their individual parts.

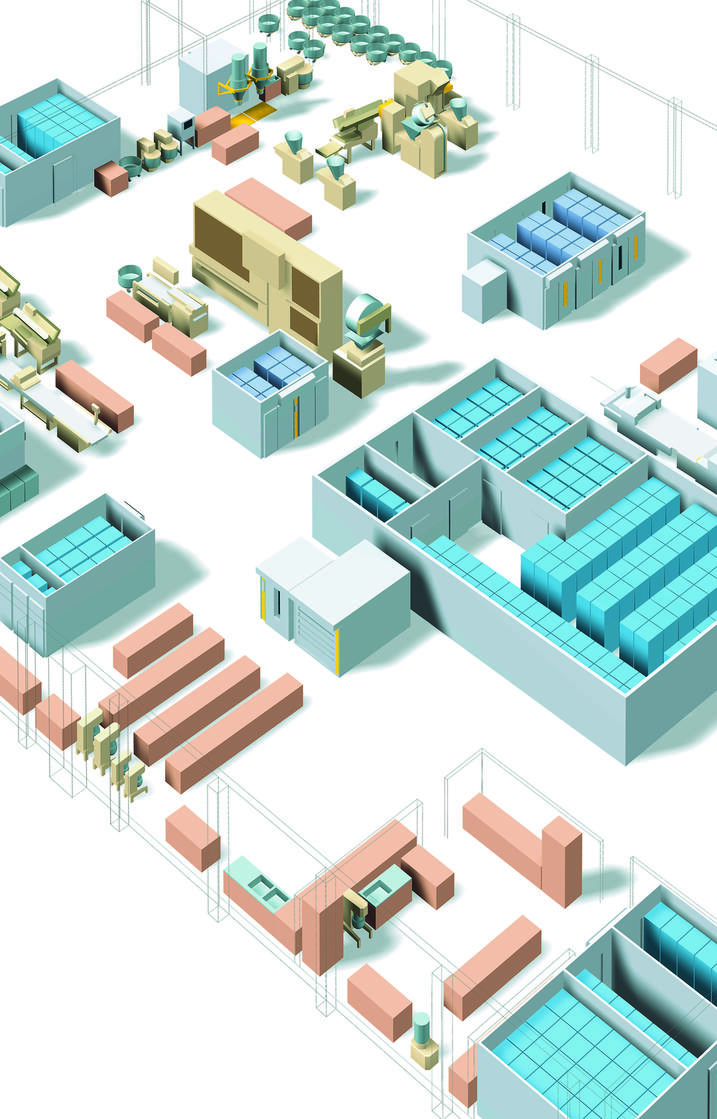

MIWE. Your expert partner for process cooling and bakery refrigeration technology

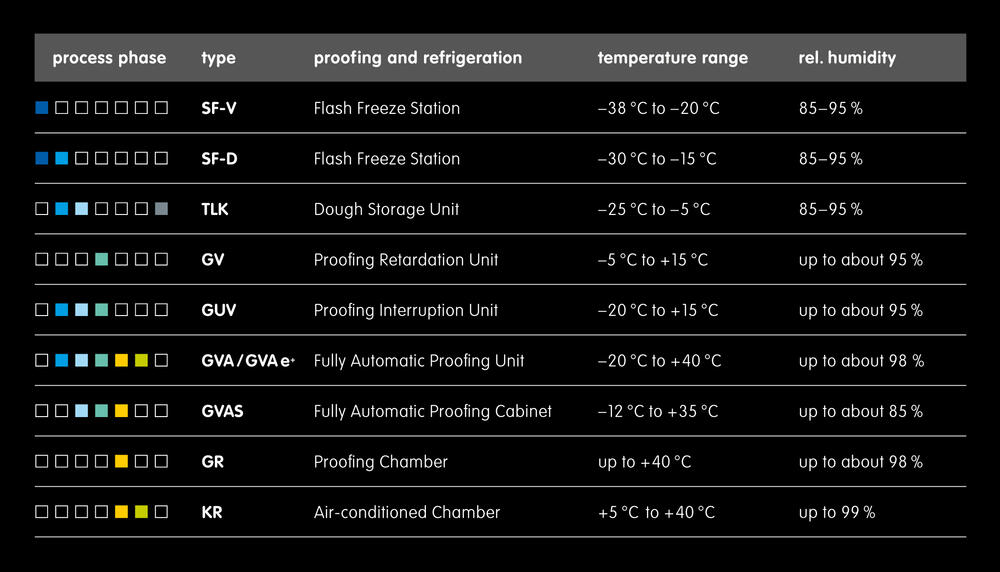

In order for the refrigeration systems in your bakery to fully exploit their advantages, i.e. to simplify your work processes, ensure optimum capacity utilisation and efficiency and even improve product quality, you need a solution tailored to your business and your requirements. MIWE's refrigeration experts determine these on the basis of a precise requirements profile that takes into account your baked goods (range, individual products, quantities, processes), your operational processes (shift systems, etc.), your spatial conditions, your business organisation (number and spatial distribution of branches, frequency of deliveries) and existing systems as well as the available budget. Based on this, we develop the solution which best suits your needs and simplifies your workflows as much as possible. It goes without saying that our product range in the field of bakery refrigeration technology includes all components for cooling, storing, proofing or freezing and therefore perfectly covers all conceivable processes and types of dough handling.

MIWE bakery refrigeration - suitable for all processes

Are you interested in our process cooling products, do you have questions about bakery refrigeration technology or would you like to optimise your production processes? Talk to us!

MIWE MIWE process cooling: All processes firmly under control

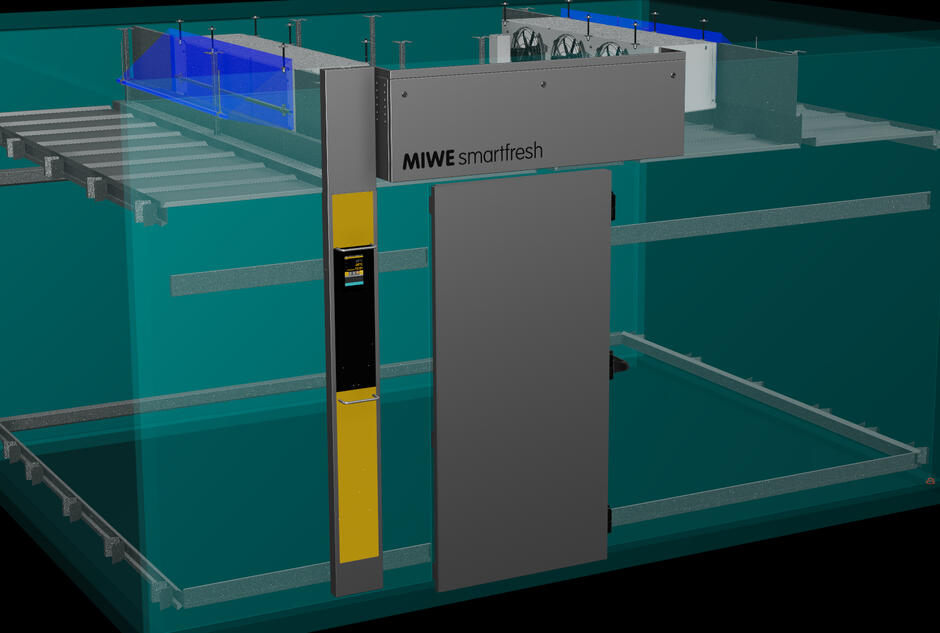

An indispensable part of many bakeries: The universal climate control specialist MIWE GVA e+

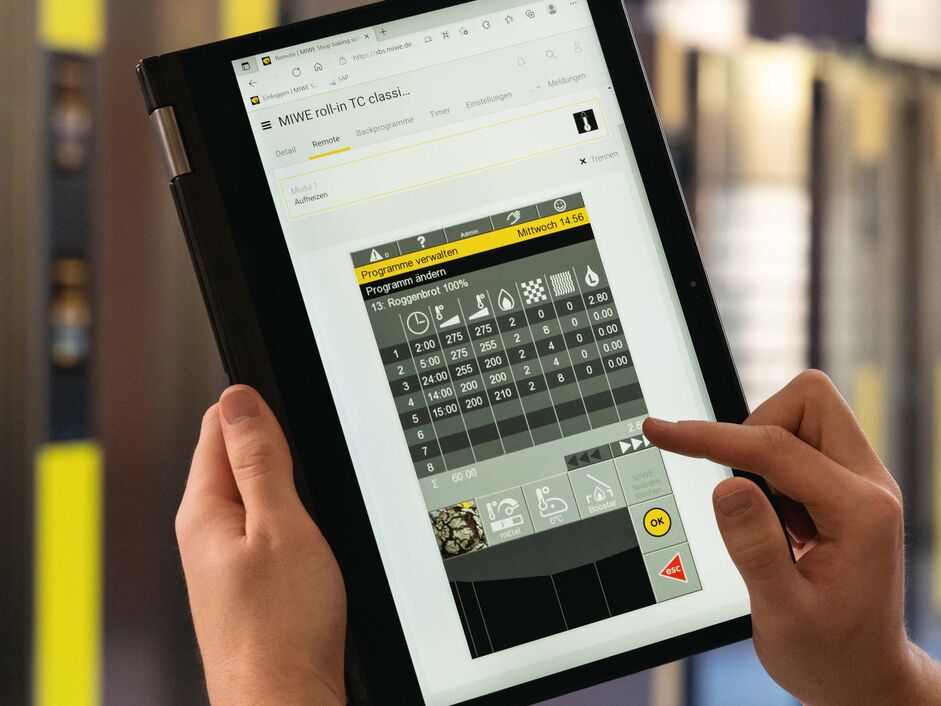

The MIWE GVA e+ automatic proofing machine takes care of all bakery refrigeration tasks from –20°C to +40°C and with a humidity range up to 98% fully-automatically and energy-efficiently. Thanks to its modern control system, even complex process sequences can be easily controlled - even remotely if required. This enables you to achieve reproducible results of the highest level. In short: The MIWE GVA e+ is your efficient helper for fermenting, delaying or interrupting fermentation, rapid cooling, bracing, freezing and long-term storage.

Flexible, durable, reliable: The advantages of our bakery refrigeration systems

- Full control over the dough flow for reliably reproducible quality

- Flexible, programmable control for customised process curves depending on the dough piece and process

- Sophisticated handling and high-quality materials for a long service life

- Safe long-term storage for tasty, wholesome and long-lasting fresh baked goods

- Customised and perfectly coordinated solutions for all stages of the baking process that only a full-service provider can offer

How MIWE bakery refrigeration technology helps you with your daily processes

Test our technologies in the MIWE Live Baking Centre in Arnstein

Pictures are patient - only in practice does it become clear whether a product delivers what it promises. At the MIWE Live Baking Centre in Arnstein, you can put all of our bakery systems and production solutions through their paces in a fully equipped demonstration bakery - using your own raw materials. The motto "Meet the experts" is to be taken literally: Not only can you ask our master bakers and dough technologists in person, we also offer comprehensive expert workshops and seminars, such as our MIWE smartfresh cooling technology, which was presented for the first time at Südback 2022.

Success stories: MIWE refrigeration on site at a local bakery

Are you interested in our process cooling products, do you have questions about bakery refrigeration technology? Talk to us!

F-Gas Regulation: Prepare for the future!

The EU's F-Gas Regulation will ban numerous refrigerants containing climate-relevant F-gases from 2025 onwards. Don't wait and see, take a forward-looking approach and bring your production up to a future-proof standard. We will be happy to advise you on your options and work with you to find the perfect solution for your needs!

Co2 cooling: Everyone's talking about it, we're just doing it - and have been for almost 10 years.

Word has probably gotten around by now that the use of Co2 refrigeration systems in bakeries has numerous advantages. Regardless of whether you are considering switching to natural refrigerants in order to fulfil the requirements of the F-Gas Regulation or for reasons of environmental friendliness, energy efficiency, operational safety or durability - such a far-reaching change always raises numerous questions and problems. It's a good thing that we at MIWE can look back on almost a decade of experience and numerous successful projects of all sizes. Perhaps your bakery will soon be one of them?